There is an endless list of things interested stakeholders can implement in their workers’ …

WCRI 2024 Preview: What I’m Looking Forward to Seeing

Socrates said, I'm the wisest man alive for I know one thing, and that is that I know nothing. …

WCRI 2024 Preview: What I’m Looking Forward to SeeingRead More

Part 3 of 5: Work Comp and the Grand Bargain – Primary Liability and Compensability

The workers’ compensation claims process has many challenges following the work injury. This …

Part 3 of 5: Work Comp and the Grand Bargain – Primary Liability and CompensabilityRead More

Part 2 of 5: Work Comp and the Grand Bargain – Understanding Work Comp Insurance

One overlooked step in reducing workers’ compensation program costs is the failure of interested …

Part 2 of 5: Work Comp and the Grand Bargain – Understanding Work Comp InsuranceRead More

Part 1 of 5: Work Comp and the Grand Bargain- A Primer

Reducing workers’ compensation program costs requires all interested stakeholders to understand its …

Part 1 of 5: Work Comp and the Grand Bargain- A PrimerRead More

4 Times When a Workers Comp Claim Should NOT Be Settled

In the workers’ compensation claims world, a commonly held belief is “the more settled claims, the …

4 Times When a Workers Comp Claim Should NOT Be SettledRead More

Avoid Ethical and Legal Pitfalls In Workers’ Comp Surveillance

Surveillance can be an effective tool to reduce costs in a workers’ compensation program. While …

Avoid Ethical and Legal Pitfalls In Workers’ Comp SurveillanceRead More

Controlling Work Comp Transportation Expense Is More Than Ordering an Uber

Monitoring and managing workers’ comp transportation expenses can drastically improve the claim …

Controlling Work Comp Transportation Expense Is More Than Ordering an UberRead More

6 Elements To Review In Your Adjuster’s Action Plan

The old adage “Time is Money” definitely applies to the handling of workers' compensation claims. …

6 Elements To Review In Your Adjuster’s Action PlanRead More

Two Very Important Steps When Managing A Catastrophic Injury Claim

When you say catastrophic injury, many people in the insurance field think of brain injuries, …

Two Very Important Steps When Managing A Catastrophic Injury ClaimRead More

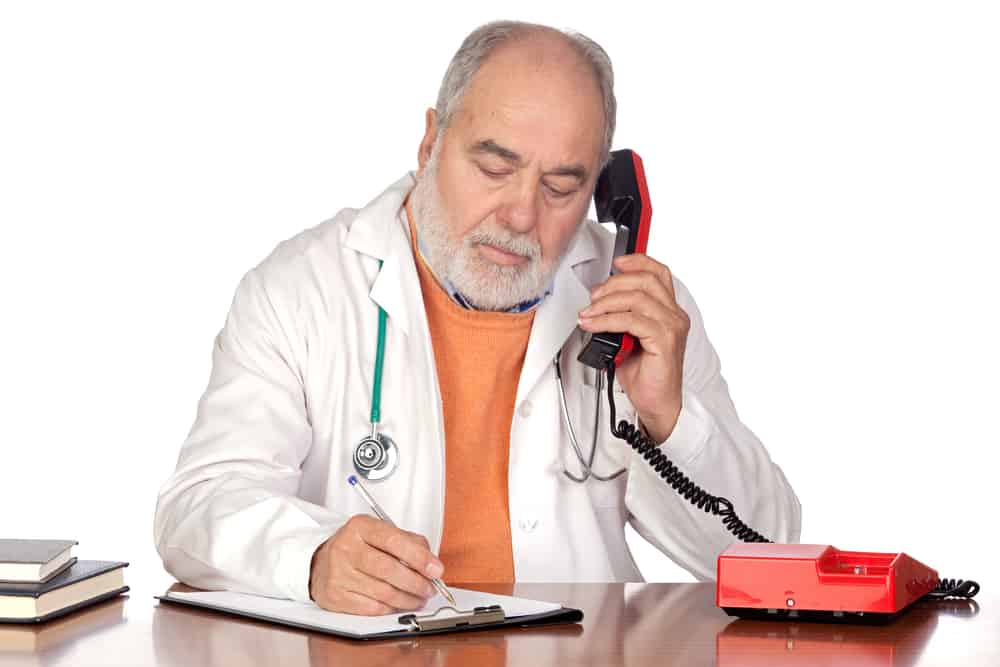

9 Questions to Ask Injured Worker’s Treating Physician

Leaving no stone unturned is critical to managing your workers' compensation costs. With the number …

9 Questions to Ask Injured Worker’s Treating PhysicianRead More

Use A Medical Advisor To Maximize Value of Independent Medical Exam

A company medical advisor can be one of the most effective tools for reducing workers’ compensation …

Use A Medical Advisor To Maximize Value of Independent Medical ExamRead More

6 Minimum Expectations For Employer Involvement in Workers’ Comp

We all know it is the employer's responsibility to purchase workers' compensation insurance …

6 Minimum Expectations For Employer Involvement in Workers’ CompRead More

Slip and Fall On Ice – Workers’ Comp Case Study

Winter presents several challenges for the claim management team and interested stakeholders …

How to Tell If You Need a Nurse Case Manager for Your Workers Compensation Claim

Nurse case managers (NCMs) coordinate medical care and determine the extent of disability. …

How to Tell If You Need a Nurse Case Manager for Your Workers Compensation ClaimRead More

8 Part Email To Send When Transitional Duty Doesn’t Work

Despite your best efforts to get medical restrictions from all treating physicians and evaluate …

8 Part Email To Send When Transitional Duty Doesn’t WorkRead More

Trends in Work Comp Legislation: Long-COVID Presumptions

The COVID-19 pandemic changed the landscape of workers’ compensation in the United States. While …

Trends in Work Comp Legislation: Long-COVID PresumptionsRead More

Is Your TPA Recovering Every Subrogation Dollar It Should?

Do you ever wonder if the claim handling quality of your insurer or third party administrator (TPA) …

Is Your TPA Recovering Every Subrogation Dollar It Should?Read More

Case Study: Renewed Hope and Return to Work

Background Alexander, a structural engineer, was inspecting an industrial worksite when a portion …

Execute a Bulletproof Workers’ Comp Claim Investigation – Part 3

This post is one in a 3-part series: Execute a Bulletproof Workers' Comp Claim Investigation …

Execute a Bulletproof Workers’ Comp Claim Investigation – Part 3Read More