The workforce is getting older. People are living longer, and their dollars aren’t necessarily …

11 Tips To Keep Aging Workers Safe, Healthy and ProductiveRead More

The workforce is getting older. People are living longer, and their dollars aren’t necessarily …

11 Tips To Keep Aging Workers Safe, Healthy and ProductiveRead More

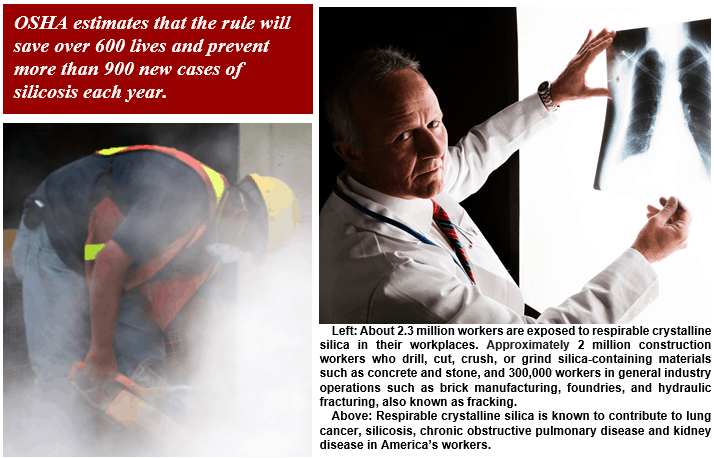

OSHA has issued a final rule to curb lung cancer, silicosis, chronic obstructive pulmonary disease …

Crystalline Silica: OSHA Acts To Protect Workers From ExposureRead More

Is there a cost to being obese? Experts say, “absolutely.” The costs of obesity can extend beyond …

One of the most common causes of workers compensation claims is the improper lifting of a heavy …

Winter is in full force and effect. With subzero temperatures hitting much of the country recently …

Hearing loss claims can be very expensive. If the loss is great enough to prevent the employee …

Do You Hear What I Hear – Prevent Hearing Loss ClaimsRead More

It’s no secret; work zones can be a dangerous place both for employees and for passers-by. Due to …

While we can tell our readers the importance of fighting fraudulent claims, and publish lists of …

Okay, as far as entertainment value goes, it may not rival late night television hosts and their …

OSHA Top 10 List Can Help Employers Avoid Costly PenaltiesRead More

All injuries are preventable. If you really think about it, if everyone did everything they were …

Injury Prevention: Look In Mirror, “You’re Looking At The Problem”Read More

We have just passed the sad 103rd anniversary of the Triangle Shirtwaist Factory Fire that occurred …

Fire Safety Lessons From One of The Deadliest Accidents In US HistoryRead More

Many workplace accidents occur because of improper lifting techniques. Workplace lifting may cause …

Lifting Safety Can Avoid A Work Comp Pain In The Neck (And Back)Read More

Electrical hazards can cause burns, shocks and electrocution. Having a comprehensive electrical …

The WC Roundup is proud to be hosting the 199th Cavalcade of Risk. This bi-weekly blog is a …

I am not 100% sure why I am intrigued by workplace safety. Throughout the course of my day I am …

Workplace safety is one of those topics where it is hard to overemphasis its importance. There can …

Having a drug-free workplace is an important step in reducing workers comp costs. Employees using …

A Drug-Free Workplace Helps Your Company And Your Workers CompRead More

Hopefully this is the last post about winter snow removal and the risk involved. I know you …